-

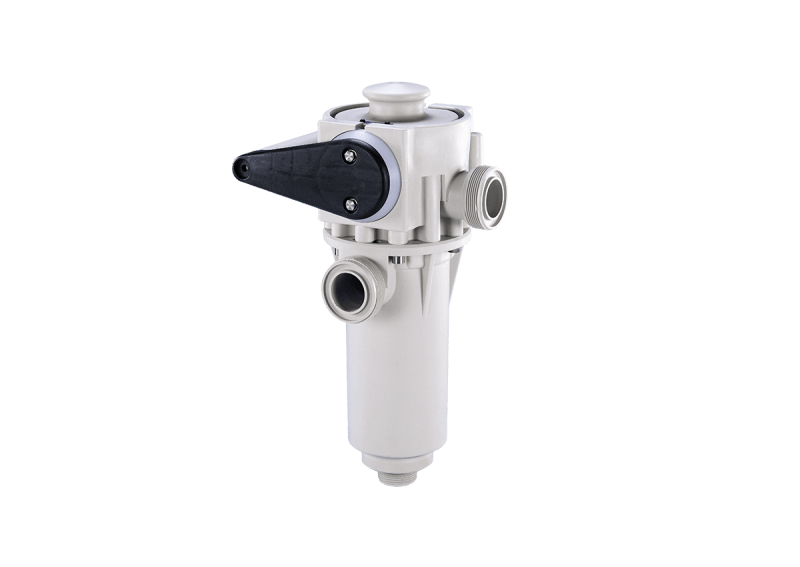

The HE-RF filter series is characterized by its novel flow concept, which was developed using detailed CFD simulations. The result is significantly higher separation rates with a smaller filer housing. The filter input and output are directed vertically downwards for direct flow to a pump. An integrated handle makes it easier to open the filter cover. The filter cartridges can be changed quickly and without any tools.

The HE-RF filter series is characterized by its novel flow concept, which was developed using detailed CFD simulations. The result is significantly higher separation rates with a smaller filer housing. The filter input and output are directed vertically downwards for direct flow to a pump. An integrated handle makes it easier to open the filter cover. The filter cartridges can be changed quickly and without any tools. -

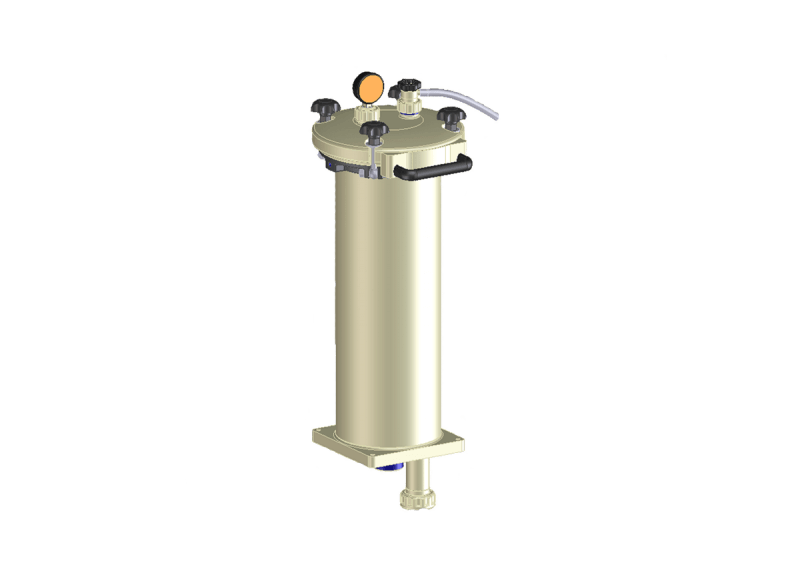

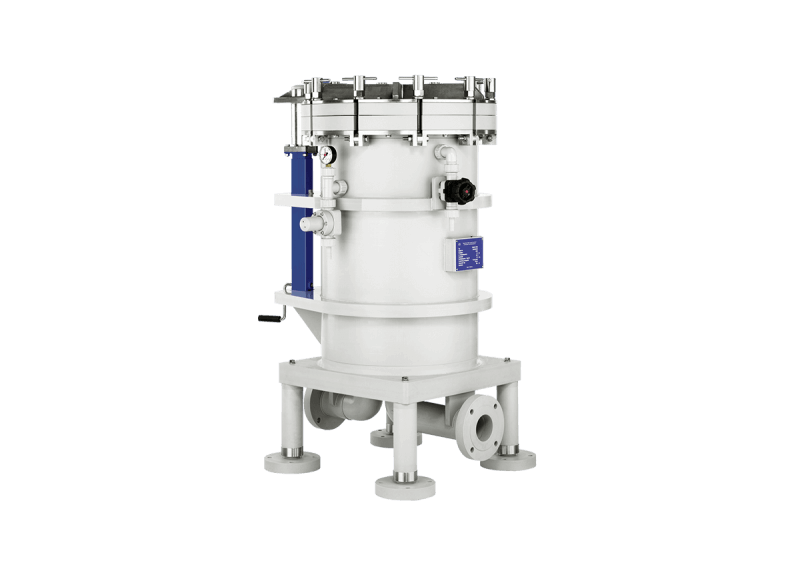

The line of products SF has proofed to be extremely reliable for use in chemical plants. These filters are characterised by compact design as well as easy and quick handling thanks to the quick fastenings, which notably reduce time for maintenance. All quick change filters are supplied with two safety switches, which prevent the filters from working without or with an open cover.

The line of products SF has proofed to be extremely reliable for use in chemical plants. These filters are characterised by compact design as well as easy and quick handling thanks to the quick fastenings, which notably reduce time for maintenance. All quick change filters are supplied with two safety switches, which prevent the filters from working without or with an open cover. -

The line of products SF has proofed to be extremely reliable for use in chemical plants. These filters are characterised by compact design as well as easy and quick handling thanks to the quick fastenings, which notably reduce time for maintenance. All quick change filters are supplied with two safety switches, which prevent the filters from working without or with an open cover.

The line of products SF has proofed to be extremely reliable for use in chemical plants. These filters are characterised by compact design as well as easy and quick handling thanks to the quick fastenings, which notably reduce time for maintenance. All quick change filters are supplied with two safety switches, which prevent the filters from working without or with an open cover. -

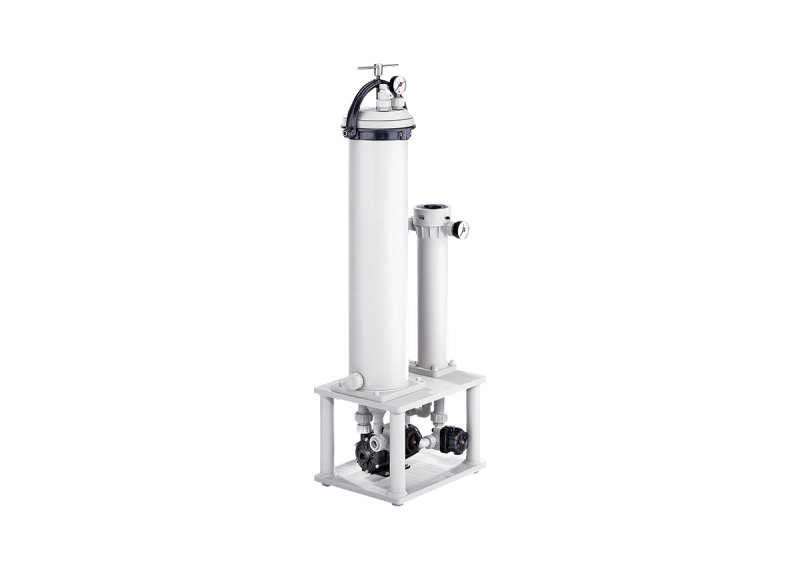

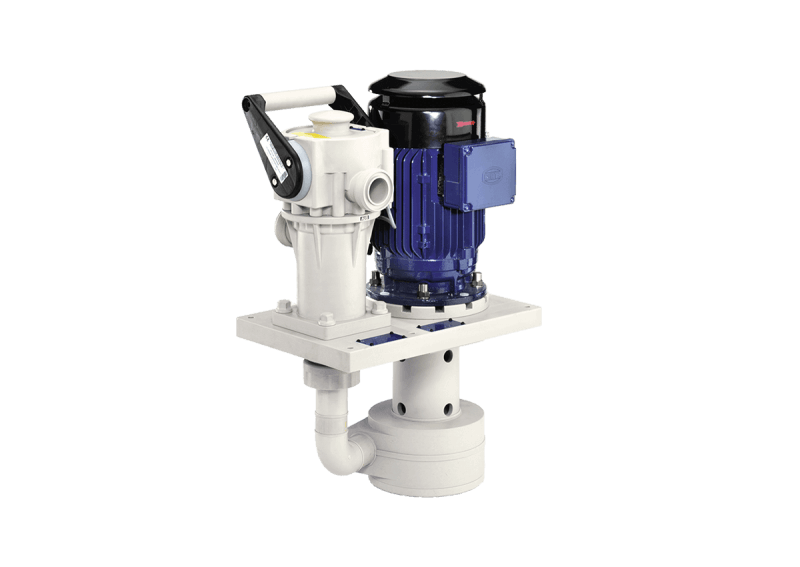

RENNER magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically.

RENNER magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically. -

RENNER magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically.

RENNER magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically. -

RENNER magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically.

RENNER magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically. -

RENNER magnetic filter pumps consists of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically.

RENNER magnetic filter pumps consists of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically. -

Renner magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically.

Renner magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically. -

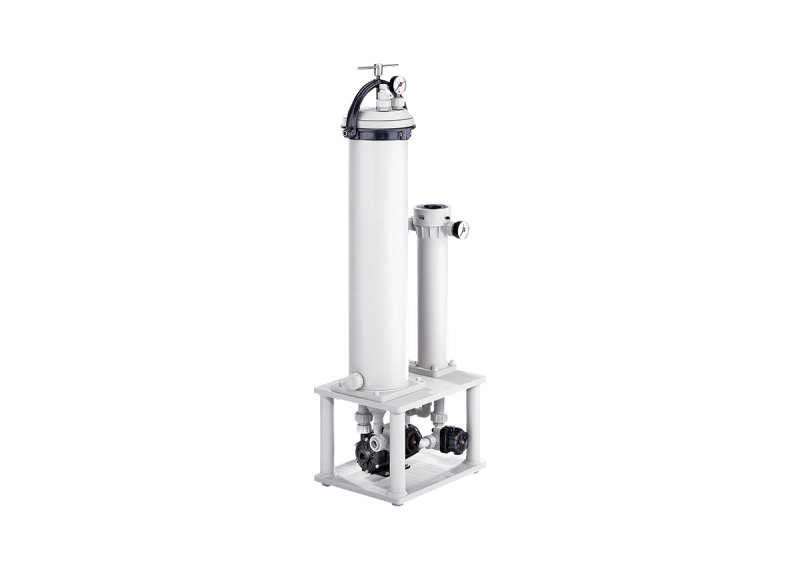

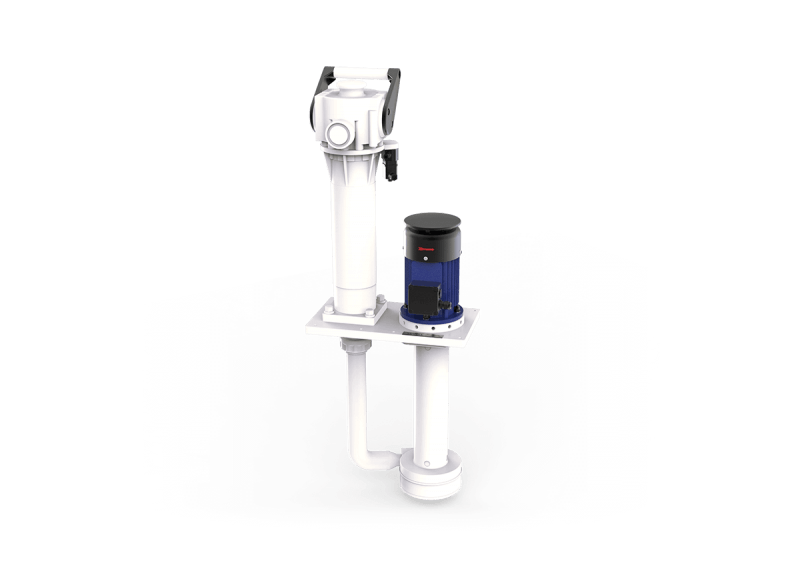

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically.

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically. -

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically.

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically.