-

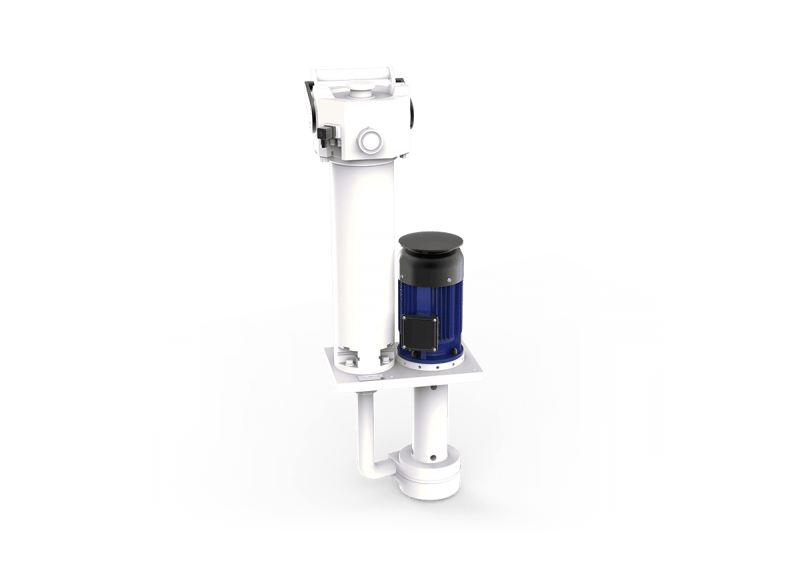

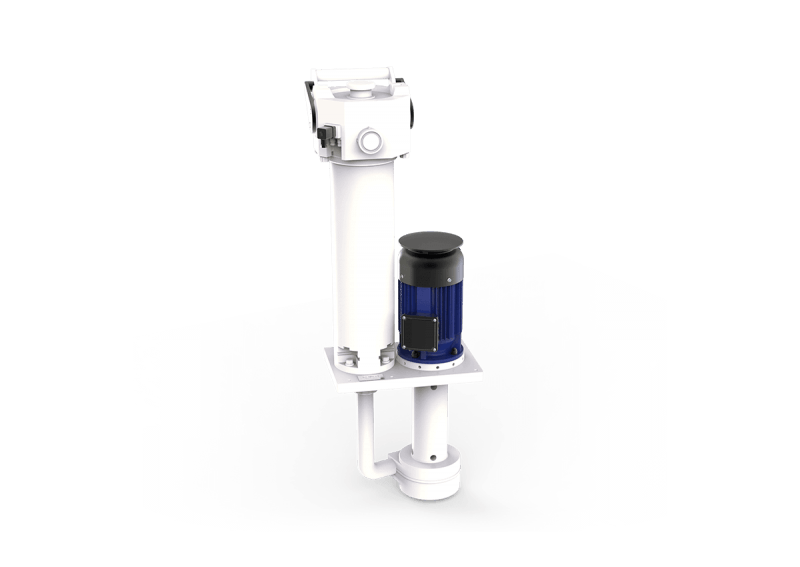

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically.

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically. -

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically.

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically. -

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically.

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically. -

The microfibres used in the pleated depth filter cartridges are particularly uniform and are thermally bonded to from a homogeneous filter layer. The resulting micropolypropylene filter matrix is considered to be the most effective deep cartridge filter and has the highest efficiency for very difficult to filter fine particles.

The microfibres used in the pleated depth filter cartridges are particularly uniform and are thermally bonded to from a homogeneous filter layer. The resulting micropolypropylene filter matrix is considered to be the most effective deep cartridge filter and has the highest efficiency for very difficult to filter fine particles.